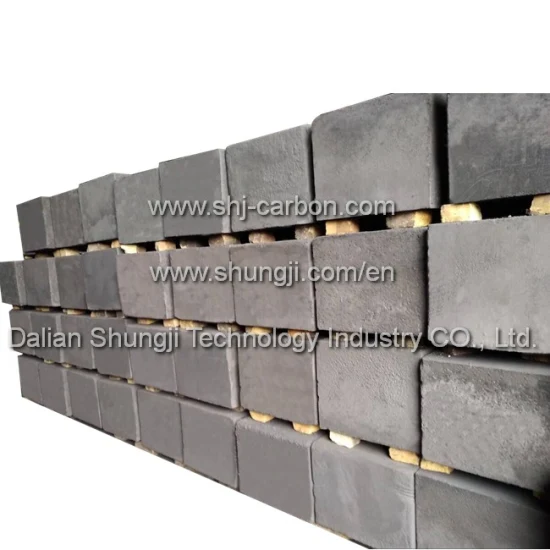

Graphite Products for Alloy Metallugy Battery Powder Carbon Fiber Composite

Basic Info.

| Flexural Strength | 68 MPa |

| Compressive Strength | 130MPa |

| Grain | 7μm |

| Density | 1.85g/ Cm3 |

| Transport Package | Wooden Packing |

| Specification | 650*550*260 |

| Trademark | SHJ |

| Origin | China |

| HS Code | 38011000 |

| Production Capacity | 1000000kg/Year |

Product Description

We supply high quality molded graphite materials as blocks and rods, we select materials for customers based on our own experimental database. We are familiar with the characteristics of molded graphite materials at home and abroad, and provide more cost-effective products on the basis ofsatisfying customer applications.

We provide graphite materials for processing graphite exothermic welding mold, exothermic welding is a simple, high-efficiency and high-quality metal joining process. The temperature of the exothermic welding reaction exceeds 2500°C. This makes high temperature resistant graphite molds the best choice. For exothermic welding molds, service life is the primary concern of customers. We can provide graphite materials with high density and high compressive strength. The graphite exothermic welding mold made of this material have a long service life and are welcomed by customers.

Materials suitable for graphite mold:

| Grades | Bulk Density | Specific Resistance | Flexural Strength | Compressive Strength | Ash | Grain Size |

| g/cm³ | μΩ.m | MPa | MPa | ppm | ||

| MV-10 | 1.6 | 10 | 15 | 28 | 0.2 | 0.8 mm |

| FM-22 | 1.80 | 9 | 38 | 75 | 0.1 | 25 μm |

Material compariso

Product Description :

Exothermic welding, also known as alumino-thermic welding, is a method of welding metal by using the heat generated by the exothermic reaction between metal oxide and aluminum.

Because in the alumino-thermic reaction, the temperature of the inner cavity of the graphite mold rises rapidly to more than 2000 ºC in a very short time, the thermal shock resistance of graphite is very important. We use fine-grained or medium grained graphite raw materials with low thermal expansion coefficient and high thermal shock resistance to process graphite exothermic welding mold, which not only improves the service life of molds, but also prevents the risk of liquid metal leakage.

Graphite machining process

| Sawing | Turning | Milling | Grinding | CNC |

SHJ has a variety of mechanical processing production lines, customized processing according to drawings, while meeting customers' different precision requirements, select the most cost-effective processing technology with the shortest processing time.

Packaging and shipping

Customized packaging according to customer needs and product characteristics, we can provide customers with laser marking, clean and sealed packaging of purified products, cartons, wooden boxes and other different packaging options.

Packaging and shipping

Customized packaging according to customer needs, wooden box, pallet packaging methods are available.

According to the cargo weight and delivery requirements, choose the most cost-effective transportation method, express, sea, airway, railway, multimodal transportation are available.

Brand Promotion

Welcome to join Shungji

FAQ1. Your specification is not very suitable for us.Please offer us specific indicators by TM or email. we will give you feedback as soon as possible.2.When can i get the price?We usually quote within 24 hours after getting your detailed requirements,like size,quantity etc. If it is an urgent order, you can call us directly. 3. Do you provide samples?Yes, samples are available for you to check our quality. Samples delivery time will be about 3-10 days.4. What about the lead time for mass product?The leadtime is based on the quantity,about 7-15 days.5.What is your terms of delivery?We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way for you. Besides that,we can also shipping by Air and Express. Notice:Pls note that the price on MADE IN CHINA is a rough price. The actual price will depends on raw materials.