Basalt Fiber Roving Glass Fibre

Basalt fiber Continuous basalt fiber (CBF) is a new type of inorganic fiber material with high performance. It is a cont

Basic Info.

| Model NO. | Basalt fiber roving |

| Usage | Building |

| Shape | Circle |

| Refractory Temperature | -260-800 |

| Thickness | 0.011-0.022mm |

| Appearance | Plate |

| Grade | Grade a |

| Transport Package | Export Standard Pallet Packaging |

| Specification | One pallet product weight 1280kg, 64 pieces |

| Trademark | HSLG |

| Origin | China |

| Production Capacity | 100000 |

Product Description

Basalt fiber

Continuous basalt fiber (CBF) is a new type of inorganic fiber material with high performance. It is a continuous fiber made of volcanic rock (a variety of basalt, natural basalt stone with oxides such as silica, alumina, calcium oxide, iron oxide and titanium dioxide) as raw materials, melted at 1450 ºC ~ 1500 ºC and pulled at high speed through platinum rhodium alloy wire drawing leakage plate. Because the fiber color is golden brown, it is also known as "golden fiber". Continuous basalt fiber has the advantages of good stability, good electrical insulation, corrosion resistance, flame retardant, high temperature resistance and low temperature resistance. It has excellent comprehensive performance, low raw material cost, natural environmental protection and high cost performance. Basalt fiber is a pure natural inorganic non-metallic material, which can be degraded into soil parent material and absorbed by soil. It is a green environmental protection product.Basalt fiber chemical composition:

| Chemical composition | Mass percentage |

| SiO2 | 52−58 |

| Al2O3 | 14−19 |

| CaO | 5−9 |

| MgO | 3.0−6 |

| Na2O, K2O | 3−6 |

| TiO2 | 0.5−2.5 |

| Fe2O3, FeO | 9.0−14.0 |

| Other | 0.09−0.13 |

Performance characteristics of basalt fiber:

1 Outstanding temperature resistance. The service temperature range of CBF is: -260 ~ 900 ºC (softening point is 960 ºC).2. Outstanding tensile strength: the tensile strength of CBF is 3800 ~ 4800 MPa.3. Natural compatibility with silicate. It belongs to silicate with cement and has stable performance in alkaline medium.4. Outstanding chemical stability, excellent acid and alkali corrosion resistance and water resistance.5. Significant thermal vibration stability. The mass loss fraction of CBF at 900 ºC is only 0.03.6. Good dielectric properties. The volume resistivity is one order of magnitude higher than that of glass fiber, and the dielectric loss tangent is 50% lower than that of glass fiber.7. Excellent wave transmission performance and certain wave absorption performance.8. It has good radiation protection function.9. Flame retardancy: in case of open fire, it will not burn.Continuous fiber is called direct yarn, which is made by high-speed drawing of wire drawing leakage plate. Basalt fiber formed by the combination of multi strand parallel precursor or single strand parallel precursor without twisting is called composite yarn, which is divided into internal retreat and external retreat products. It is mainly used for winding all kinds of pipes, cans, gas cylinders, resin reinforcement materials, weaving all kinds of square cloth, grid cloth, composite reinforcement, repair and reinforcement in building structures, SMC, short cut yarn, etc

Comparison between basalt fiber and other fibers

| Performance | Basalt fiber | E glass fiber | Aramid fiber | carbon fibre |

| Density(g/cm3) | 2.65 | 2.7 | 1.45 | 1.78 |

| Service temperature(ºC) | -269~700 | -60~450 | 250 | 200 |

| Thermal conductivity W/(m·K) | 0.031~0.038 | 0.034~0.040 | 0.04~0.13 | 5~185 |

| Resistivity (20ºC)/Ω·m | 1×1012 | 1×1011 | 3×1013 | 2×15-5 |

| Tensile strength(MPa) | 3800~4800 | 3100~3800 | 2900~3400 | 3500~6000 |

| Elongation(%) | 1.25~3.2 | 1.3~2.0 | 2.8~3.6 | 2.7~3.0 |

| Elastic modulus(GPa) | 83.5~110 | 58~75.5 | 70~140 | 230~580 |

| Sound absorption coefficient | 0.9~0.99 | 0.8~0.93 | ― | ― |

Basalt fiber roving

Continuous fiber is called direct yarn, which is made by high-speed drawing of wire drawing leakage plate. Basalt fiber formed by the combination of multi strand parallel precursor or single strand parallel precursor without twisting is called composite yarn, which is divided into internal retreat and external retreat products.Specification and model: BFR 13-1200-p, primary color returningWhere: BFR is basalt fiber Twistless roving;13 is the diameter of basalt fiber, unit: μ m. Can produce 13 ~ 22 μ m;1200 is the linear density of roving, in tex ( g / km), which can be customized. Generally, the direct yarn is not more than 2400tex and the ply yarn is not more than 4800tex;P is the purpose of fiber, which is determined by the model of surface treatment agent;The primary color is non dyed twistless yarn, and others are dyed black twistless black yarn;External retreat is the process of retreat, and others are internal retreat.

Technical indicators

| fiber diameter(μm) | Linear density(tex) | Breaking strength(N/Tex) | Elongation(%) | Moisture content(%) |

| 13~22 | 600~4800 | ≥0.4 | 2.0 | ≤1 |

Application:

1. It is mainly used for winding various pipes, cans and gas cylinders;2. As a resin reinforced material, basalt steel bars and various profiles are manufactured;3. Weave all kinds of unidirectional cloth, grid cloth and geotextile, which are used for repair and reinforcement in building structures;4. Weave plain cloth and twill cloth;5,SMC,BMC,DMC;6. Short cut yarn is made for concrete reinforcement, etcRaw material homogenization production line Tank furnace wire drawing production line

Professional testing personnel and equipment

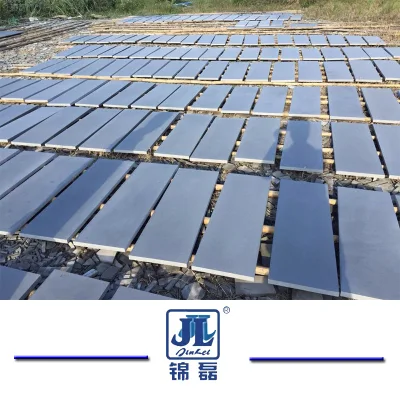

Basalt fiber oyster raft and deep-sea cage Marine wind power and marine photovoltaic power generation

Send to us